The Internet of Things and the Industrial Internet of Things have been making headlines like the Monday “breaking news” on TV. And too many of its random blogs, papers, and general technical terminologies have made it way more complicated than it actually is.

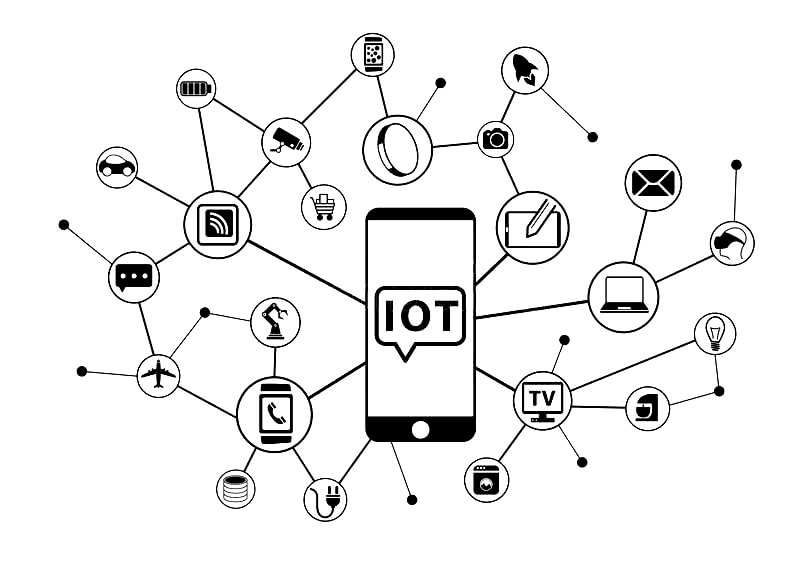

Am I also going to do the same for you with this blog? Oh noooooo….We are going to make this a little fun! Let me rephrase the basics for you, the “internet of things” is nothing but a chain of physical things or objects that are interconnected via the god of all things, the Internet.

Every other tech person is screaming around in conferences: “Automation is the future,” but what is he/she specifically talking about? They are talking about industrial IoT solutions (IIOT). And now we have come to our second segment of the game.

IIOT solutions for the manufacturing industry or top industrial IoT companies are automation and the infusion of the internet in various industrial sectors. For example, consider an automobile, a tool made for humans by humans but assembled by monitored and controlled robots and other pieces of machinery. In short, a network of connected devices in the industrial sector

What is IIOT? Iiot solutions

The Industrial Internet of Things is basically a subset of IOT. It enables industries and companies to improve operational efficiency and dependability. In this sector, there’s a heavy emphasis on machine-to-machine (M2M) communication, big data, and machine learning for industrial development. The fact that linked devices on IIoT networks send data without human-to-human or human-to-computer contact is what differentiates them.

IIOT Examples

Some of the top examples of IIOT and IOT are:

- Sensors

- Computers

- Machines used in manufacturing

- Agriculture

- Mission-critical applications

- Nuclear and energy management systems

Industrial IoT solutions

Now let’s lose the semantics and get down to what IIOT is doing for us. Industrial IoT is empowered by cutting-edge technologies like AI, big data, cloud computing, IoT, edge computing, advanced robotics, blockchain, cybersecurity, and cognitive computing. Yes, IIOT fulfils all the physicists’ and experimenters’ dreams.

Let’s check out the key demographic that is empowering it to be No. 1 in the world. The key market growth drivers of this sector are:

- Rapid industrialization

- Increased use of IIoT solutions by sectors

- Manufacturing, automotive, healthcare, logistics, and construction

- growing emphasis on productivity improvement

- Cost reduction

- Employee safety

IIoT technology can offer mission-critical systems early warnings about the environment, such as high levels of carbon monoxide in a plant.

IoT Solutions For The Manufacturing Industry

IIOT has seen some revolutionary developments since the automation industry took over. Every other business is now either heavily dependent on new IoT solutions or at least doesn’t fail to Google and keep track of the top industrial IoT companies.

The IIoT comprises industrial applications such as robots, medical devices, and software-defined manufacturing processes. IIoT is applied in the manufacturing industry to manage assets and supply chains. It facilitates real-time communication between suppliers, manufacturers, storage facilities, delivery firms, and clients, as well as centralized asset management.

That’s not all; the Internet of Things reduces human error in inventory management as well. IIoT asset management decreases the need for human labor and lowers the cost of products and services. In simple words, consider IIOT like your mutual funds; you have got to invest smartly, in the beginning, to reap the rewards in the future.

Industrial IoT solutions

IIOT extends beyond the typical consumer products and physical device internetworking associated with IoT. According to experts, the IIoT will experience more acceptance than the IoT. This is because industrial companies have a strong motivation to boost their financial results and return on investment, reduce labor expenses, and boost productivity.

Automation will continue to be used in supply chain management, manufacturing, product distribution, and material handling. Organizations may enhance current operations and create more successful business models by integrating linked systems, devices, and sensors into business processes.

Organizations must spend money on software programs like Rialtes, IBM, and many more to do this. Don’t wait now; the future of everything is here.